how does vapor honing work

Vapor blasting is also commonly known as wet blasting liquid honing vapor honing dustless blasting or slurry blasting. Read Customer Reviews Find Best Sellers.

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube

Vapor honing is also known as vapor blasting aqua blasting wet blasting slurry blasting and dustless blasting.

. Find Deals on vapor blasting kit Facein on Amazon. Abrasive selection is made based on desired surface roughness or aesthetically desired finish. Combining water and abrasive together forms a slurry which is propelled at the part surface using compressed air.

Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure. To slow down the corrosion process a corrosion-inhibiting primer should be applied as soon as the surface has. There will still be visible surface topology and minimal layer lines.

Vapor Honing or wet blasting is a process utilized for precision surface finishing. Well generally speaking nothing. Rolls Royce used it to strengthen turbine blades before assembly into jet engines.

Vapor blasting is a process that was developed during the second world war. This helps preserve the original shape and fine detail of your valuable parts. Ad But Did You Check eBay.

It is also referred to. One of the drawbacks of vapor blasting is that it can accelerate the corrosion process. The vapor blasting process provides the highest quality soft surface finish.

Water abrasive and compressed air are 3 ke. Also known as wet abrasive blasting vapor blasting vapor honing dustless blasting or slurry blasting. It is important to note that chemical vapor smoothing re-distributes surface material to provide a sealed smooth surface but it does not create a polished surface.

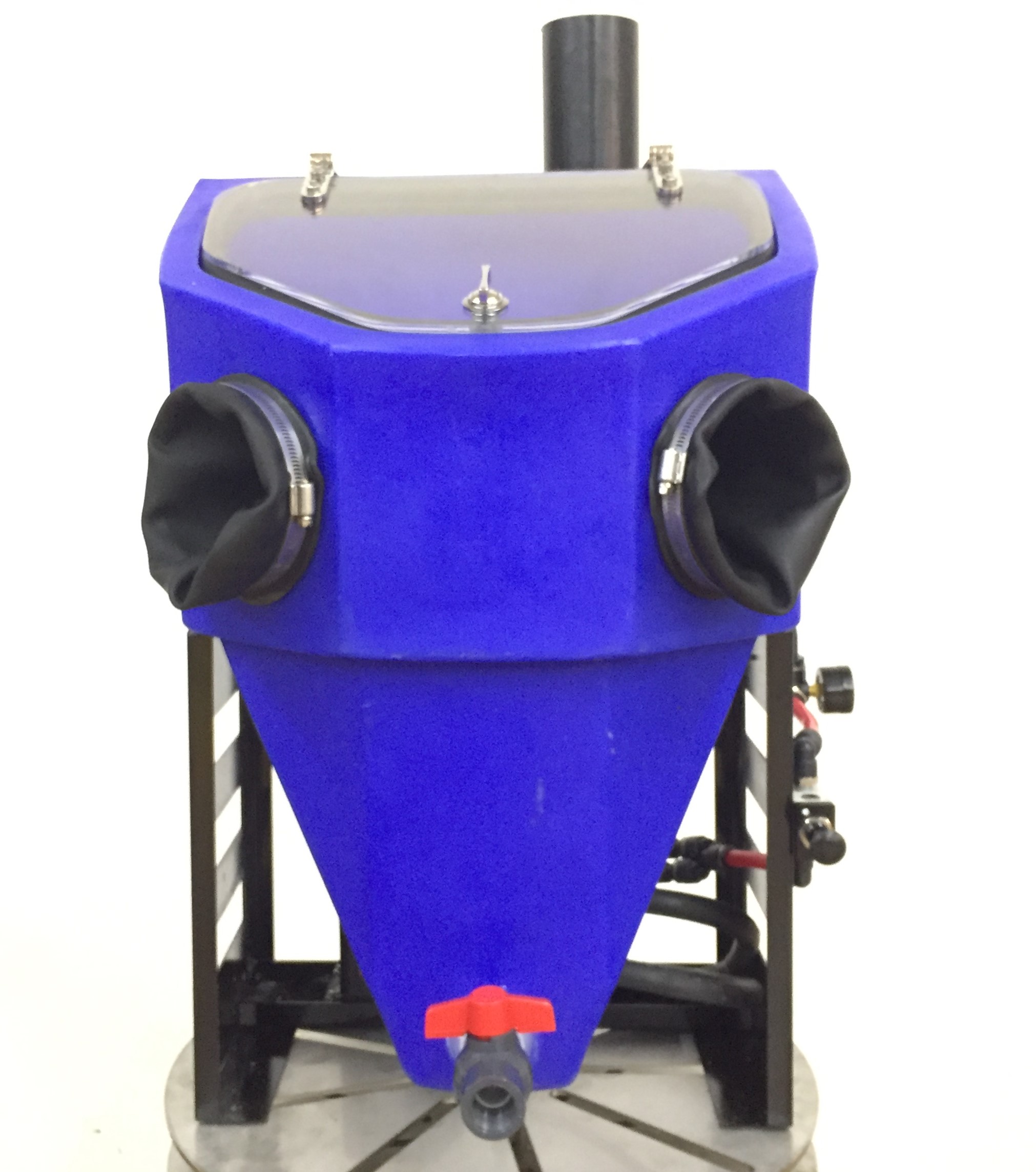

Single 220v 13 amp 110v also available. The Liquid Vapor Honing process is applied to metals for the following reasons. It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting.

Basically this is a technology that involves the blasting of abrasive material blast mixed with pressurized water. Ad Browse Discover Thousands of brands. Vapor honing does not remove metal its a finish restoration process.

Vapor blasting also known as vapor honing is a blasting process using a mix of water and blasting media such as glass beads or aluminum oxide. Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like sandblasting. ALL OUR MACHINES Feature.

What is Vapor Honing. Vapor honing is also an excellent option to remove very fine burrs tool marks or. It is commonly used for cleaning aerospace parts and surfaces.

Vapor blasting also known as wet blasting liquid honing or dustless blasting is a process that uses pressurized water and abrasive material to remove contaminants corrosion residue or coatings from a surface. Whats the difference between Vapour Honing Wet Blasting and Aqua Blasting. All Stainless Steel Construction.

A specially designed high volume pump mixes abrasive media with water. 750 x 750 x 750. Liquid Vapor Honing.

In some studies chemical vapor smoothing improved material surfaces by 800-1000. Vapor honing has many advantages such as being dust free preserving the surface finish of the part and creating a brilliant finish. How Does It Work.

Vapor blasting will remove the super hard layer of oxidation and the remnants of factory paints or clearcoats and reduce the amount of sanding needed to prepare for buffing. They are all the same they all describe a process of cleaning parts using a media suspended in water. Although both sandblasting and vapor blasting can cause corrosion problems the metal surfaces prepared by vapor blasting tend to corrode faster.

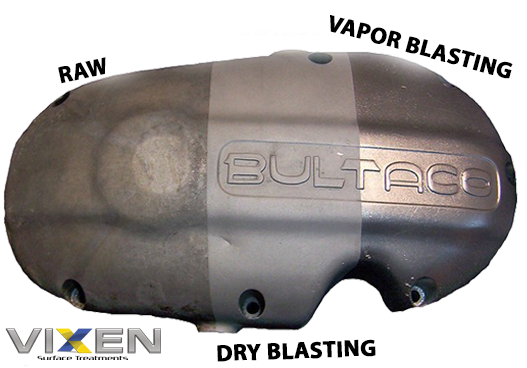

Over 80 New. By suspending fine abrasive media in water and detergents the blasted surface is left with an attractive satin finish that is smooth and almost polished due to a peening-effect that doesnt leave fingerprints like sandblasted parts do while being more resistant to future. As you can see from all these names vapor honing is the wet version of dry blasting.

Treat the surface to make it metallurgically clean prior to electro-polishing electro-plating or other coating processes. The key to vapor blasting is that the finish is produced through flow of water borne abrasives. Check Out Vapor Hone On eBay.

Remove machining or directional polish lines or marks on such objects as molds and dies for metal plastics or rubber. Vapor honing is also known as wet blasting it is safe environmentally friendly what vapor honing does is use water and fine high quality abrasives such as glass bead or ceramic powders and air all recycled and reused in our Vapor honing technologys 3630 cabinet. Find Great Deals Now.

Vapor honing also known as vapor blasting wet blasting or wet honing is a process that mixes an abrasive media with water to create an unparalleled finish and is much gentler on parts than acid baths or sandblasting. The process was developed in Europe a number of years ago and that might be where the misleading vapor part of the name came from. It was initially used in industry to create surface tension in parts to strengthen them.

Wet Blasting is an industrial process in which pressurized wet slurry is applied to a surface for various cleaning or finishing effects. Vapor Honing produces a finer finish due to the. Wet blasting vapor blasting is a process for removing contaminants from a surface or finishing a surface using pressurized water and abrasive blast media.

The parts are blasted and photos of the finished work are sent. Vapor blasting is a superior process with significant advantages over traditional dry sandblasting. Fine abrasives between 2 and 400 micron are suspended in water and forced at the material at high velocity to remove impurities such as heat treat scale.

This Is The New eBay. Get Matts plans here.

How Good Is The Micro Hone Vapor Honing Technologies Youtube

Vapor Hone 1000 Wet Blasting Equipment Blast Wash Systems

A Simple Introduction To Vapor Honing Issuu

What Exactly Is Vapor Honing 5 Things You Should Know

Vapor Blasting Services Wet Blasting Vapor Honing Technologies

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Vapor Honing Bonehead Performance

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

Vapor Blasting What It Is Costs And Shipping

Slurry Blasting Vapor Blasting Equipment For Sale Vapor Honing Technologies

Vapor Honing Services What Is Vapor Honing And Does It Work

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Honing Blasting Superfly Garage